What is smartPCN?

Obsolescence Management is the focus of the COGD (Component Obsolescence Group Deutschland) e.V. COGD aims to minimize the occurance and impact of the non-availability of components within products. For example, during the product life-time, components necessary for future production become obsolete due to the evolution of technology, economics, or legislation and regulation.

Suppliers release Product Change Notifications (PCNs) to give notice of a change in a component specification or that its manufacture is about to cease. In the latter case the PCN may also be known as a Product Discontinuation Notice (PDN). Suppliers frequently use a proprietary PCN format which is unique to them, and yet electronic communication using standard protocols and formats has been used in other situations for decades. So why not exploit this standardization opportunity?

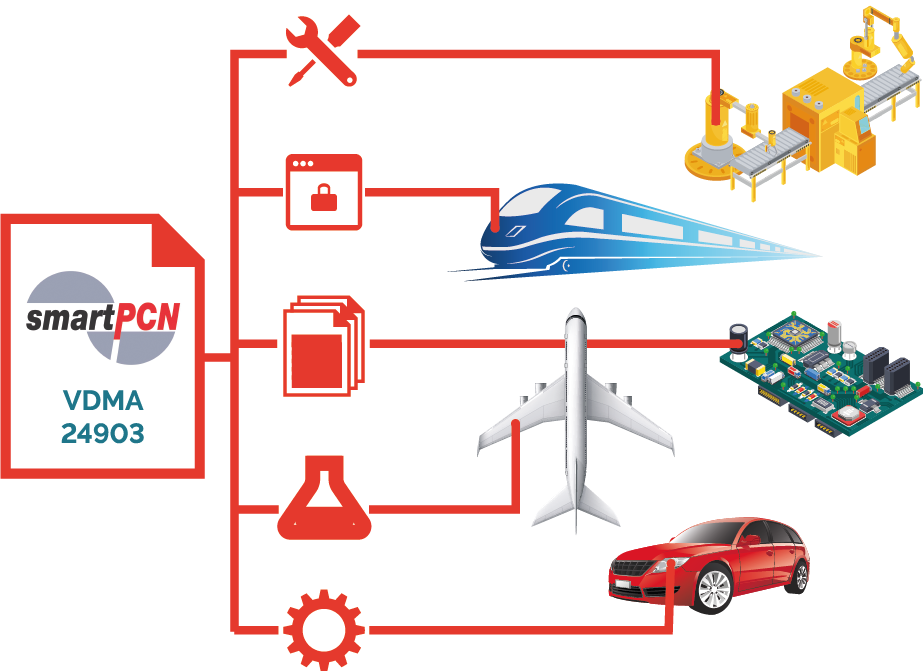

This is why COGD is working to establish smartPCN as the international standard for automated exchange and processing of PCNs. This will bring benefits for everyone in the industry. The smartPCN standard was developed by the smartPCN working group. The Intellectual Property in the smartPCN standard belongs to COGD but COGD encourages its use openly and without costs.

The smartPCN standard defines a machine readable record based on the Extensible Markup Language (XML). A smartPCN record can be send via email or automated data exchange, for example between enterprise resource planning (ERP) systems of the companies in the supply chain. The content of each record is structured to allow its automated processing and distribution. A smartPCN record can propagate through the supply chain and this allows both the reverse tracing of the source of arisings and forward warning of potential impacts. The end-to-end resiliance, the agility to anticipate and resolve problems, and business advantage of the supply chain are all enhanced.

The smartPCN standard provides the opportunity to use automation to capture past experience of when events occurred in the life cycle and what costs were involved in resolving the problem. This data, information and knowledge may be used to inform risk management and cost forecasting, across the supply chain, for future assemblies, products or systems of similar type. The smartPCN standard allows similar principle to be applied to the known or likely timing of other critical events. For example as may be associated with RoHS or REACH, and the important process of material management and material declaration.

smartPCN Container File includes:

- part & process changes

- item numbers

- life cycle data

- descriptions

- standardized categorizations

- replacement parts

- documents like drawings/specs

- technical data

- original PCN/PDN documents

smartPCN Summary

The smartPCN standard developed by COGD is making a powerful contribution to the transition from reactive to proactive obsolescence management by enabling efficiencies in both the external AND internal PCN-related communication of a company. Moreover, research conducted by COGD for two years prior to release of the standard has resulted in flexibility to manage other information in support of processes such as configuration management and change control.